Why Does Little League Use Aluminum Bats?

For young baseball players in Little League, using the proper bat is crucial for their safety and enjoyment of the game. Aluminum bats are commonly used, but many parents and coaches wonder why.

Little League uses aluminum bats because they are lightweight yet durable, allowing kids to generate good bat speed. The bats also have a large sweet spot for making solid contact.

Safety standards regulate aluminum bat performance to keep ball speeds within acceptable limits for youth play. With proper batting techniques taught by coaches, aluminum bats provide a great way for Little Leaguers to learn batting fundamentals.

In this article, we’ll explore the reasons behind Little League’s decision to use aluminum bats, examining the safety measures in place, the benefits of using these metal bats even for young players, and the ongoing discussion around this controversial topic.

Key Takeaways

- Aluminum bats are preferred in Little League due to their superior exit velocity and impact on game dynamics, as noted by industry experts.

- Economic considerations play a significant role in bat selection, with leagues balancing supplier pricing against quality and long-term financial implications.

- The construction of baseballs, including seam height and core composition, is crucial for player performance and preference, influencing league decisions.

- The evolution of baseball manufacturing has been shaped by a history of trial and error, with a focus on durability and performance through rigorous field testing.

- Trade secrets in baseball production, while maintaining a level of secrecy, ensure consistent quality and are vital to the collaboration between leagues and manufacturers.

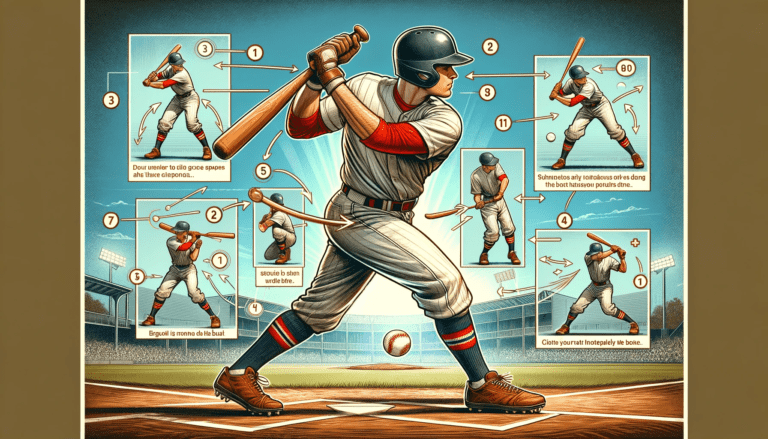

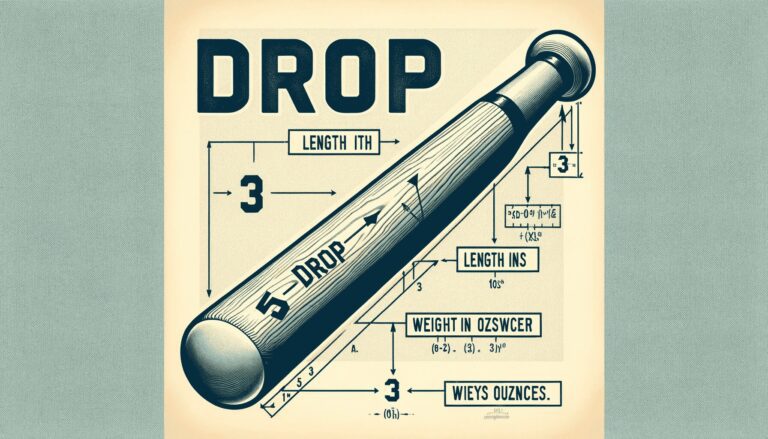

The Science of Swing: Analyzing Bat Performance

Exit Velocity and Bat-Ball Collision

Understanding the interaction between bat and ball is crucial in baseball, particularly when assessing bat performance.

Exit velocity is a key metric, representing the speed at which the ball leaves the bat after impact. This measurement is directly influenced by the bat’s material and construction.

For instance, the ‘trampoline effect‘ of composite baseball bats can lead to higher exit velocities compared to aluminum bats.

Several factors contribute to the exit velocity during a bat-ball collision:

- The stiffness and rebound properties of the bat

- The mass distribution along the bat’s length

- The speed of the bat swing by the player

These elements combine to determine how much power is transferred to the ball, affecting how far and how fast it will travel.

Field tests and statistical analyses have shown that different bat materials can significantly alter the game’s dynamics, with aluminum bats often preferred for their consistent performance and durability.

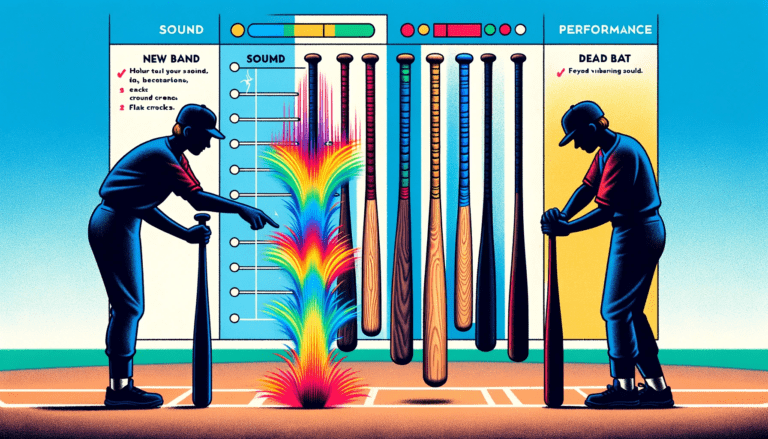

Field Testing and Statistical Analysis

In the quest to understand the performance of aluminum bats in Little League, field testing and statistical analysis play pivotal roles.

Teams and suppliers alike scrutinize the exit velocity of balls and their trajectory post-collision with the bat. This data is crucial in assessing the efficacy of different bat materials.

The process typically involves:

- Measuring the exit velocity of the ball off the bat

- Analyzing the ball’s trajectory and distance traveled

- Comparing the performance across various bat models

Statistical analysis helps in identifying trends and outliers in performance. For instance, a significant drop in power stats over a period could indicate an issue with the bat or ball quality.

The collaboration between leagues and suppliers ensures that the bats meet the desired standards of play.

Ultimately, the data collected from field tests and statistical analysis informs decisions on which bats provide the optimal balance of safety, performance, and cost-effectiveness for Little League players.

The Impact of Bat Material on Game Dynamics

The choice of bat material extends beyond mere preference; it fundamentally alters the dynamics of the game.

Aluminum Baseball Bats, favored in Little League, significantly affect the exit velocity of the ball compared to their wooden counterparts.

This has several implications:

- Increased hitting distances: The ball travels further when struck by an aluminum bat, which can lead to more home runs and extra-base hits.

- Altered pitching strategies: Pitchers may need to adjust their approach, knowing that batters have the potential to hit the ball harder and further.

- Defensive adjustments: Infielders and outfielders must be prepared for quicker ball speeds off the bat, which can change the way they position themselves and react during the game.

The interaction between bat and ball is a critical component of baseball, and the use of aluminum bats in Little League introduces a distinct set of challenges and opportunities for players and coaches alike.

As the game evolves, so too does the equipment, with leagues continually assessing the impact on play and striving for a balance between performance, safety, and the spirit of the sport.

Read Also: Why Do They Use Aluminum Bats in College Baseball

Economic Curveballs: Cost Considerations in Bat Selection

Comparing Supplier Pricing

When Little League teams step up to the plate, the choice of bat can be as strategic as the swing of the metal bat itself.

Cost is a critical factor in selecting the right bat, and comparing supplier pricing is a complex task.

Here are some considerations:

- Quality vs. Price: The balance between durability and affordability is delicate. A higher price tag might indicate a bat that withstands the rigors of the game longer, reducing the need for frequent replacements.

- Bulk Purchases: Leagues often negotiate bulk pricing, which can significantly lower the cost per bat. This requires upfront investment but can lead to long-term savings.

- Supplier Relationships: Establishing a good relationship with suppliers can lead to better deals, exclusive offers, or early access to the latest bat technology.

In the end, the decision often boils down to a trade-off between immediate cost and anticipated performance gains.

As one league president put it, after rigorous testing and analysis, it came down to pricing when two baseballs stood out as top contenders.

This underscores the importance of thorough evaluation and strategic purchasing decisions in the world of Little League and college baseball too.

The Influence of Budget on Equipment Quality

In the realm of Little League baseball, the correlation between budget constraints and equipment quality cannot be overstated.

Budgets dictate the caliber of baseball equipment that leagues can afford, often resulting in a trade-off between cost and quality.

For instance, a higher budget allows for the purchase of premium bats that not only enhance performance but also ensure safety and durability.

- Supplier pricing plays a pivotal role in this equation. Leagues must navigate the complex market, where the cost of a quality bat can significantly impact their financial resources.

- The baseball equipment market is projected to reach a staggering $21 billion by 2028, growing at a rate of 5.0%. This growth is segmented across various products, including bats, helmets, and gloves, each varying in quality and price.

- Long-term financial implications are also a consideration. Investing in higher-quality bats may seem costly upfront but can lead to savings over time due to their longer lifespan and reduced need for replacements.

Ultimately, the challenge for Little League administrators is to balance the budget without compromising the safety and effectiveness of the players’ equipment.

This delicate balance is essential for maintaining the integrity of the game and ensuring a positive experience for all participants.

Long-term Financial Implications for Leagues

The decision to use aluminum bats in Little League is not only a matter of performance but also a significant economic consideration.

Leagues must weigh the initial costs against the long-term benefits when selecting equipment.

Aluminum bats, while more expensive upfront, do not break as easily as wooden bats, leading to fewer replacements per wood bat and, consequently, cost savings over time.

- Durability: Aluminum bats can withstand thousands of hits without losing their shape or effectiveness.

- Replacement Costs: The reduced frequency of bat replacements can lead to substantial savings for leagues.

- Consistency: Players benefit from the uniform performance of aluminum bats, which can reduce the need for frequent adjustments.

In the context of overall major league baseball expenditures, the choice of bat material becomes a strategic financial decision.

For instance, the Western Canadian Baseball League (WCBL) spends a significant amount on baseball annually, indicating the scale of investment in equipment.

By opting for aluminum bats, leagues can allocate resources more efficiently and ensure a more predictable budget over the seasons.

Read Also: How Fast Does a Baseball Come Off the Bat

Pitching Preferences: How Ball Construction Affects Play

Seam Height and Pitch Control

The height of a baseball’s seams can significantly influence a pitcher’s grip and control over the ball.

Pitchers often prefer raised seams for better command of their off-speed pitches, as they provide the pitcher a firmer grip. However, the trend towards lower seams in college and some high school leagues has made it challenging for pitchers who rely on this tactile advantage.

- Raised seams offer a better grip, leading to improved pitch control.

- Lower seams are becoming more common, aligning with professional standards.

- The choice of seam height affects the sustainability and durability of the baseball.

Manufacturers like Diamond have experimented with different stitching techniques to find a balance that satisfies both pitchers and hitters. The D1-CL LS model, for example, features a low seam but aims to be neutral in terms of advantage.

Ultimately, the ongoing debate over seam height reflects the diverse preferences within the sport and the subtle ways equipment can impact gameplay.

The Search for the Perfect Core

The quest for the perfect core in baseball manufacturing is a meticulous process that involves balancing performance with durability.

The core, or ‘pill’, is the heart of the baseball, and its composition is critical to how the ball behaves in play.

Traditionally made of cork, rubber, metal or a combination of both, the core’s construction can significantly affect the ball’s exit velocity and overall feel for both pitchers and batters.

Several steps are taken to ensure the core meets the high standards required for league play:

- Raw materials selection: Choosing the right combination of cork and rubber to provide the desired bounce and hardness.

- Field testing: Subjecting the baseballs to rigorous testing to analyze performance metrics like exit velocity and pitch control.

- Collaboration with leagues: Working closely with leagues to tailor the baseball to their specific needs and preferences.

Finding the right core is a balance of science and secrecy, with manufacturers often keeping the exact details under wraps to maintain a competitive edge. However, the end goal remains the same: to create a baseball that is consistent in quality and enhances the game’s dynamics.

Leather Quality and Ball Grip

The tactile relationship between a pitcher’s fingers and the baseball is pivotal for control and spin.

High-quality leather is crucial for enhancing baseball glove durability and performance. The right leather not only affects the longevity of the ball but also how it interacts with the pitcher’s grip. Full-grain leather, known for its durability, stands out as a preferred material.

Several factors contribute to the effectiveness of a baseball’s grip:

- The process of rubbing up balls with special mud before games.

- The quality of the cowhide, which can affect how well the ball takes the mud.

- The firmness of the laces, which can influence a pitcher’s control.

Umpires and players alike recognize the importance of a well-prepared ball. A ball with better cowhide means the mud works better, enhancing the grip and allowing for more movement on the pitch.

Durability and sustainability are also key, as a ball with loose seams that constantly needs replacement is not practical for gameplay.

Conclusion

In the world of Little League baseball, the choice of aluminum bats is a multifaceted decision influenced by factors such as performance, safety, and cost-effectiveness.

As we’ve explored throughout this article, aluminum bats offer a unique combination of durability and lighter weight than wood one, allowing young players to swing faster and hit the ball further.

They also tend to be more cost-effective in the long run due to their resilience against wear and tear. Moreover, the preference for aluminum bats is reinforced by their safety profile, as they are less prone to shattering compared to their other wooden bat counterparts.

Ultimately, the adoption of aluminum bats in Little League is a testament to the sport’s evolution, prioritizing the needs and safety of its budding athletes while maintaining the integrity and competitive spirit of the game.

Frequently Asked Questions

Why are aluminum bats preferred in Little League baseball?

Aluminum bats are preferred in Little League due to their lighter weight, which allows younger players to swing more easily and hit the ball with greater speed and power, known as higher exit velocity. They are also more durable and cost-effective over time than wood bats.

How does bat material affect the dynamics of a baseball game?

Bat material affects game dynamics by influencing the exit velocity of the ball and the distance it can travel. Aluminum bats typically result in faster and farther hits compared to wooden bats, which can change the defensive strategies and outcomes of games.

What factors are considered when selecting a baseball supplier?

When selecting a baseball supplier, factors such as the quality and performance of the baseballs, cost, durability, and how the balls affect players’ abilities to pitch and hit are considered. Field testing and statistical analysis help determine the best supplier.

How does the construction of a baseball affect pitchers?

The construction of a baseball, particularly the seam height and the quality of the leather, affects pitchers’ grip and control. Higher seams can provide better command of off-speed pitches, while quality leather can improve grip and ball movement.

What is the significance of the core of a baseball?

The core of a baseball, often made from cushioned cork, affects the liveliness and flight of the ball. A well-constructed core can result in a more dynamic and exciting game, as the ball will travel further when hit, challenging both pitchers and fielders.

Are there trade secrets involved in baseball manufacturing?

Yes, there are trade secrets in baseball manufacturing. Manufacturers often protect proprietary information about the materials and processes used to create baseballs, aiming to produce high-quality, consistent products that perform well in games.