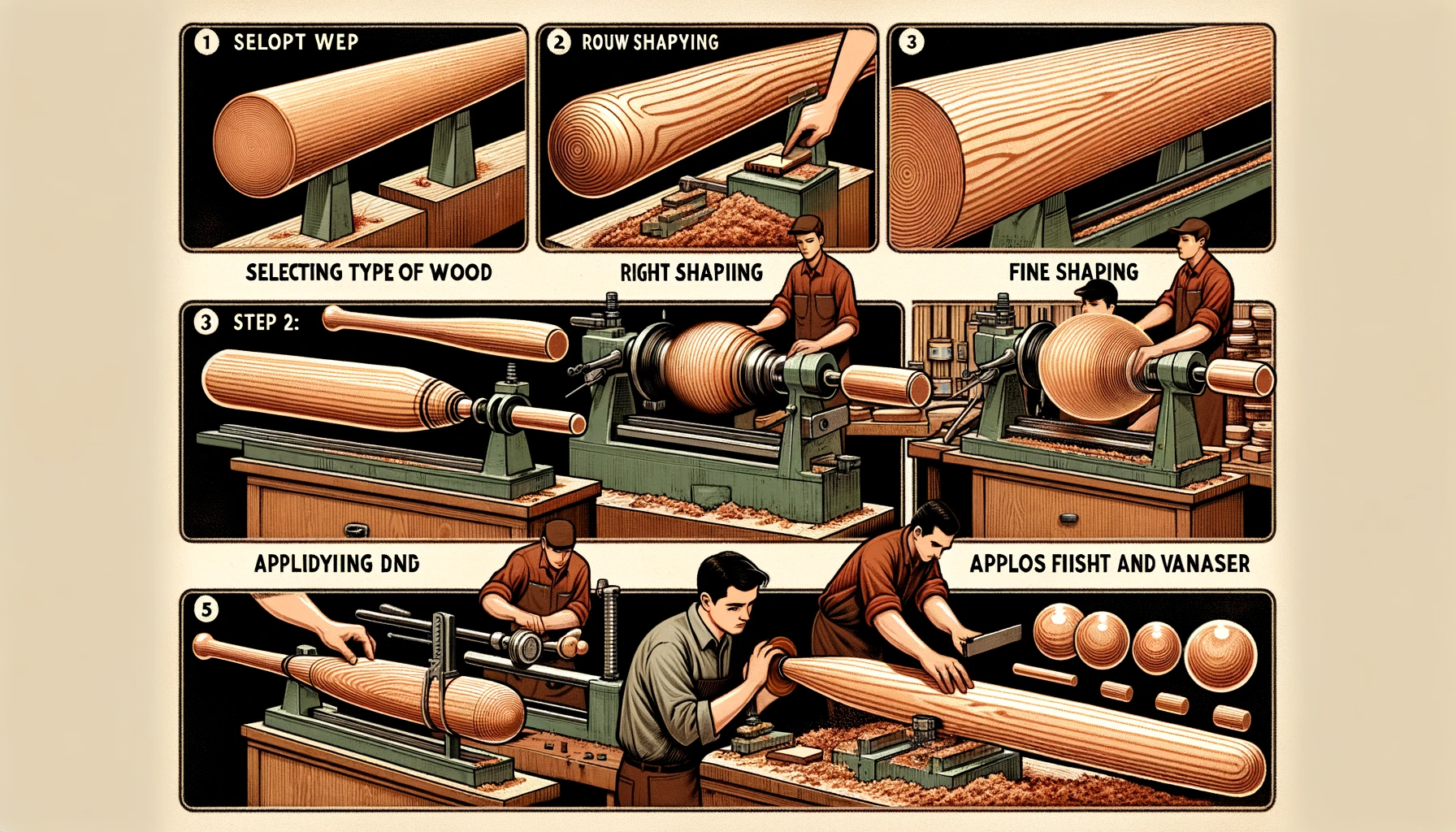

How to Make a Wooden Baseball Bat?

Looking to make your own wooden baseball bat? Buying one from the store can get pricey, and it’s tough to find the exact fit for your swing and style.

Using a bat made by someone else can feel a bit off like it’s missing that personal touch that connects you to the game. Why stick with the usual when you can make a bat that feels like it was made just for you?

In this step-by-step guide, we will help you craft your own wooden baseball bat. We’ll cover everything from picking the right wood to the final touches of sanding and finishing.

By the end of it, you’ll have a bat that’s just right for your game. Get ready to make your own special bat of baseball.

Key Takeaways

- Choosing the right lathe is crucial for bat making, with options like CNC for automation and traditional lathes for hands-on craftsmanship.

- Quality wood selection and understanding grain and texture are fundamental for a bat’s durability and performance.

- Shaping a bat involves precise carving techniques to ensure balance and a 6-layer paint finishing process for aesthetic excellence.

- Personalization through painting, staining, and adding grips or emblems allows for a custom touch to your baseball bat.

- Lathes offer versatility beyond bat making, allowing for the creation of miniature bats, unique wooden items, and the expansion of woodturning skills.

Choosing the Right Lathe for Your Baseball Bat

Types of Lathes for Baseball Bat Crafting

When selecting a lathe for crafting wooden baseball bats on, it’s essential to consider the various types available on the market.

The CNC baseball bat lathe is renowned for its precision and automation, making it an excellent choice for mass production.

On the other hand, traditional wood bat lathes offer manual control, allowing artisans to impart a unique touch to each bat.

The selection includes:

- CNC baseball bat lathes for automated precision

- Traditional wood bat lathes for manual craftsmanship

- Medium-sized lathes for versatility in other woodturning projects

Each type of cnc lathe caters to different aspects of bat making, from the Mophorn Wood Lathe which is known for its variable speed and soft startups, to compact mini CNC lathes that fit in smaller spaces.

Understanding the specific requirements of your bat crafting project will guide you to the most suitable lathe choice.

Features of Baseball Bat Lathes

When selecting a lathe for making baseball bats, it’s essential to consider the specialized features that these machines offer.

Programmable settings are a key feature, allowing for the creation of bats with consistent precision and adherence to specific dimensions. This is particularly important for ensuring that each bat meets professional standards.

Compact models, such as mini CNC lathes, are designed to fit into smaller workspaces while still providing the automated functions necessary for bat making.

These models are an excellent choice for those with limited space but who still require the efficiency and consistency of CNC technology.

The versatility of baseball bat lathes is also a significant factor. While they are specifically engineered for bat making, their capabilities extend to a variety of woodturning projects.

This allows craftsmen to expand their range of products and services, utilizing the same machine for multiple applications.

Advantages of Using a Dedicated Lathe

When crafting a baseball bat, using a dedicated lathe can make a significant difference in the quality and consistency of the final product.

A dedicated lathe ensures that each bat is balanced and crafted to exact specifications, which is crucial for optimal performance.

These specialized machines are designed to handle the unique contours and dimensions required for baseball bats, offering precision that general-purpose lathes might not provide.

The robust construction of a baseball bat lathe is another advantage. Built to withstand the rigors of professional bat making, these lathes use durable materials that contribute to their longevity and consistent performance.

This is particularly important for those who are looking to produce bats on a commercial scale or for personal projects over a long period.

Moreover, while these lathes are tailored for bat making, they also offer versatility for other woodturning projects.

Their adaptability makes them suitable for a range of applications, from bowl production to log processing, showcasing the broad utility of these specialized machines.

Read Also: What Do Baseball Players Spray on Their Bats

Preparing the Wood for Bat Making

Selecting Quality Wood

The foundation of a superior baseball bat begins with choosing the right wood. 100% European Beechwood is renowned for its durability, outperforming Maple and Birch by 8% in independent lab tests.

When selecting wood, consider the following:

- The type of wood: Birch plywood is a popular choice, offering a balance between hardness and flexibility.

- The wood’s finish: Look for wood with an ultra-hard Diamond Gloss finish for enhanced durability.

- Grain quality: An Ink Dot mark is a sign of wood that meets or exceeds MLB quality standards, indicating straight grains.

Ensure the wood is pre-sanded and free from imperfections. If customization is needed, such as adding holes, choose suppliers that offer these services at no extra charge.

Remember, the quality of your bat is a direct reflection of the quality of wood you start spinning bat with.

Understanding Wood Grain and Texture

The grain and texture of the wood are critical factors in crafting a baseball bat that not only looks good but performs well on the field.

Understanding the wood’s natural pattern is essential for predicting how it will respond to being shaped and used in play.

Different woods offer varying degrees of hardness, flexibility, and weight, which can affect the bat’s swing and durability.

- Hickory, for instance, is known for its dramatic grain and color, making it a popular choice for those seeking durability and a distinctive look.

- Maple and birch are also commonly used, with birch providing a good balance between hardness and flexibility.

- Beechwood has been lab-tested to be more durable than both maple and birch, making it an excellent option for those looking for longevity in their bat.

When selecting your wood, consider the grain orientation. Wood with straight grains that exceed MLB quality requirements, often indicated by an ink dot, is ideal.

This ensures that the bat will have the strength needed to withstand the impact of the ball without breaking.

Additionally, the finishing process can enhance the wood’s natural beauty and protect it from the elements, with some wood bats even featuring a diamond gloss finish for an ultra-hard protective layer.

Pre-treatment and Conditioning of Wood

Before you begin the actual bat-making process, pre-treatment and conditioning of the wood are crucial steps to ensure the durability and performance of your baseball bat.

Proper conditioning stabilizes the wood, reducing the risk of warping or cracking during and after the bat is crafted.

To prepare your wood for bat making, follow these guidelines:

- Start by selecting a high-quality wood, such as European Beechwood, known for its durability. Ensure that the wood has been lab-tested for strength and has no significant grain lines that could lead to splits.

- If your wood comes with a protective paper backing, remember to peel it off before you proceed.

- Condition the wood by applying an ultra-hard Diamond Gloss finish or a similar sealant. This not only hardens the surface but also provides a layer of protection against moisture and wear.

- Allow the wood to rest in a controlled environment to acclimate, which can help minimize future movement or distortion.

By taking the time to properly prepare and condition your wood, you’re setting the stage for a high-quality, custom baseball bat that will stand the test of time.

Read Also: How to Hang Baseball Bats on Wall

The Art of Shaping a Baseball Bat

Mounting the Wood on the Lathe

Before the actual shaping of the baseball bat can begin, it is crucial to properly mount the wood on the lathe.

Ensuring the wood is securely fastened and perfectly centered is key to a balanced bat.

Follow these steps to mount your wood blank:

- Inspect the wood for any defects or irregularities that might affect the mounting process.

- Position the wood between the lathe’s headstock and tailstock, making sure it’s aligned along the lathe’s center axis.

- Use the lathe’s locking mechanism to secure the wood in place, checking for any movement or wobble.

- Adjust the tailstock pressure to ensure the wood is held firmly but not so tight that it causes damage.

Once the wood is mounted, take a moment to rotate it by hand to verify that it spins evenly.

This preliminary check can prevent issues during the turning process and is a step that should not be overlooked.

Carving Techniques for Optimal Balance

Achieving optimal balance in a baseball bat is crucial for performance. The key to a well-balanced bat lies in the precision of the carving process.

Careful removal of wood from the billet ensures that the bat’s weight is distributed evenly from the knob to the barrel.

Here are some steps to consider during the carving phase:

- Begin by defining the bat’s profile, considering the desired length and weight.

- Gradually remove material, frequently checking the balance point.

- Use calipers to measure the diameter of the bat at various points to ensure consistency.

Remember, the goal is to create a bat that feels comfortable in the player’s hands and allows for swift, controlled swings.

The taper of the bat, from the barrel to the handle, should be smooth and gradual. This not only contributes to the bat’s balance but also to its aesthetic appeal.

After carving, it’s essential to test the bat’s balance by holding it parallel to the ground at the handle. A balanced bat will remain steady and not tip towards the barrel or the knob.

Finishing Touches: Sanding and Polishing

Once your baseball bat has been carved to perfection, it’s time to focus on the finishing touches that will make it both visually appealing and comfortable to handle.

Sanding is the first step in this process, smoothing out any rough areas and preparing the surface for polishing. Start with a coarse grit sandpaper and work your way to a finer grit for a smooth finish.

After sanding, polishing is essential to protect the wood and give your bat a professional, glossy appearance.

Applying an ultra-hard diamond gloss finish can significantly increase the durability of your bat. Remember to apply the finish evenly and allow it to dry completely before handling.

Here are a few tips to ensure a top-quality finish:

- Always sand in the direction of the wood grain to avoid scratches.

- Use a tack cloth to remove all dust between sanding and applying the finish.

- Consider multiple coats of finish for added protection and shine.

With these steps, your bat will not only look great but also stand up to the rigors of the game.

Customizing Your Baseball Bat

Personalization Options

Once you’ve crafted your wooden baseball bat, personalizing it can make it truly unique. Engraving your name or a special message is a popular option, turning a functional sports tool into a memorable keepsake.

Here are some ways to add a personal touch:

- Engraving designs or text for a custom look

- Choosing a special font that reflects your personality

- Adding symbols or logos that have personal significance

Remember, the personalization process is not just about aesthetics; it can also involve functional customizations.

For instance, adjusting the weight or the grip to suit your playing style can make a significant difference in your game.

When considering personalization, always ensure that any modifications do not compromise the bat’s integrity or performance.

Painting and Staining Techniques

After shaping your baseball bat to perfection, the next step is to give it a unique look that reflects your style. Painting and staining are excellent ways to protect and personalize your bat.

When choosing paints or stains, consider the following:

- Acrylics are versatile and come in a wide range of colors, perfect for vibrant designs.

- Stains can enhance the natural beauty of the wood grain, offering a more traditional look.

- Chalk paints provide a matte finish and can be easily distressed for a vintage effect.

Before applying any paint or stain, ensure that the bat is sanded smoothly and free from dust. For best results, apply a primer to the wood to help the color adhere better and last longer.

Once the primer is dry, you can begin painting or staining your bat. Use even strokes and work in sections to avoid drips and streaks. If you’re using paint, multiple thin coats will yield a more professional finish than one thick coat.

After the paint or stain has dried completely, consider applying a protective sealant. This could be an ultra-hard diamond gloss finish or a simple clear coat, depending on your preference and the level of durability you desire.

A sealant will not only protect the color but also help to shield the wood from the elements, ensuring that your custom bat remains in great condition for as long as possible.

Adding Grips and Emblems

After selecting the perfect wood and shape for your baseball bat, adding grips and emblems can provide both functional benefits and a touch of personal flair.

Choose grips that enhance your hold during the game, ensuring better control and comfort.

Consider the following when selecting your grip:

- The material of the grip, such as rubber or synthetic, for durability and feel.

- The thickness of the grip to match your hand size and preference.

- The pattern and texture for additional grip and moisture control.

Emblems, on the other hand, are a great way to showcase your team spirit or personal brand. They can be engraved or attached to the bat, offering a unique customization that stands out on the field.

Remember to place them where they won’t affect the bat’s balance or your grip. Finally, explore the latest trends, like the MOONMAN Bat Grip from JAW Bats, which promises to bring a new standard in style to your bat grips.

Conclusion

Crafting a wooden baseball bat is both an art and a science, requiring precision, patience, and the right tools.

Throughout this guide, we’ve explored the intricacies of selecting the perfect wood, the importance of using a dedicated wood lathe just for shaping, and the finishing touches that make your bat not only functional but also a piece of craftsmanship.

Whether you’re a seasoned woodworker or a DIY enthusiast, the process of making your own baseball bat can be immensely rewarding.

With the knowledge of lathe types, materials, and construction techniques, you’re now equipped to step up to the plate and create a bat that could hit a home run in both performance and aesthetics.

Remember, the key to a successful DIY baseball bat project lies in the attention to detail and the passion for the craft. Swing for the fences and enjoy the satisfaction of playing with a bat that’s truly your own creation.

Frequently Asked Questions

What are the different types of lathes available for crafting baseball bats?

The primary types of lathes for crafting baseball bats include the CNC baseball bat lathe, known for precision and automation, and the traditional wood bat lathe, which allows for manual control and artisanal craftsmanship.

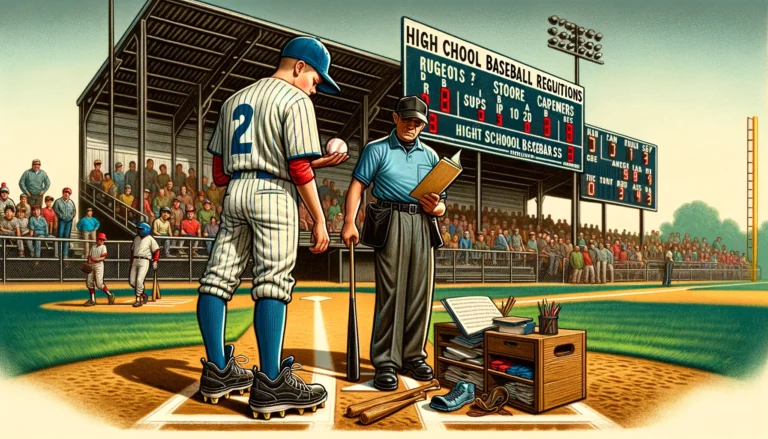

What features should I look for in a baseball bat lathe?

Look for features like Diamond Pressed barrels for compressed wood, Ink Dot for grain quality, a 6 Layer Paint Finishing process, Built-In Grip to reduce vibrations, and the use of durable materials like 100% European Beechwood.

Why should I use a dedicated lathe for making baseball bats?

Using a dedicated lathe ensures that the bats meet professional standards, with precision shaping for balance and performance. These lathes are designed for the unique task of bat making, providing consistency and quality for commercial bats.

How do I prepare the wood before mounting it on the lathe?

Select quality wood with the right grain and texture, then condition and pre-treat it to ensure it’s ready for the lathe. This preparation is crucial for the bat’s durability and performance.

Can I personalize my wooden baseball bat after shaping it?

Yes, you can personalize your bat with options such as painting, staining, adding grips, and emblems. These customizations can add a unique touch and enhance the bat’s appearance.

What are some other creative uses for my lathe beyond making baseball bats?

Apart from making baseball bats, your lathe can be used to turn miniature wooden bats used for decor, craft unique wooden items, and expand your woodturning skills to create a variety of projects like bowls or log pieces.